Rebound’s team of highly skilled technicians has extensive experience in the tear down, inspection and rebuilding of most types of General Electric and Siemens/Westinghouse valves. We are adept at reverse engineering and the manufacturing of new parts for the rebuild process.

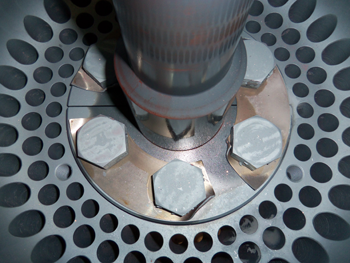

GE Intercept Valves

GE Control Valves

GE Re-Heat Stop Valves

GE High Pressure Float Valves

GE Powell Valves

Rebound Industrial Maintenance has a staff of experienced field machinist and the accessibility to the equipment to get the job done. Our field machinist will come to your site to complete repairs, and are well established as the solution for critical time-dependent jobs. Rebound Industrial Maintenance can eliminate maintenance tear down, outside facility transportation, and re-installation costs. Our diagnostic and mechanical expertise can assist you with any mechanical challenge.

Rebound has the resources and know-how to come to you sight to complete a wide variety of change out and alignment services. We can install your existing components on the spot, and complete the rebuild of removed components in our facility. Let us help keep you prepared for a quick change out for the next mechanical failure.

Rebound Industrial Maintenance has the know-how and experience to perform a variety of repair and rebuild services. Among the mechanical components we service:

Gear Boxes

Pumps

Compressors

Rolls

Heat Exchangers

Rebound Industrial Maintenance’s experience in Power Generation repair and outage work is extensive. We are outage specialists. We understand and respond to critical path work, and can get the job done in time to get back on line.

Our power generation experience includes:

Rebuild/Inspection of Reheat Stop Valves

Boiler Feed Pump Line Boring

Re-Machining Pressure Faces for Pressure Seal Heads

Stop Valve, Control Valve and Intercept Valve Bushing Replacement

Shroud Repairs

Keyway Repairs

Hydrogen Seal Housing and Ring Repairs

IGV Stop Valve Collar Manufacture

Standard Hole Repair

Shim Plate and Key Manufacture for Turbine Alignment

Rebound Industrial Maintenance is a maintenance machine shop, not a production shop. We specialize in the repair of industrial machinery, with the capability to design, reengineer, or reverse engineer parts to return equipment to OEM condition. Rebound Industrial Maintenance manufactures the irreplaceable parts that are critical to getting our customers back to work. If it is broken, we can fix it. If you think it can’t be done, let our team of experienced repair specialists prove you wrong.